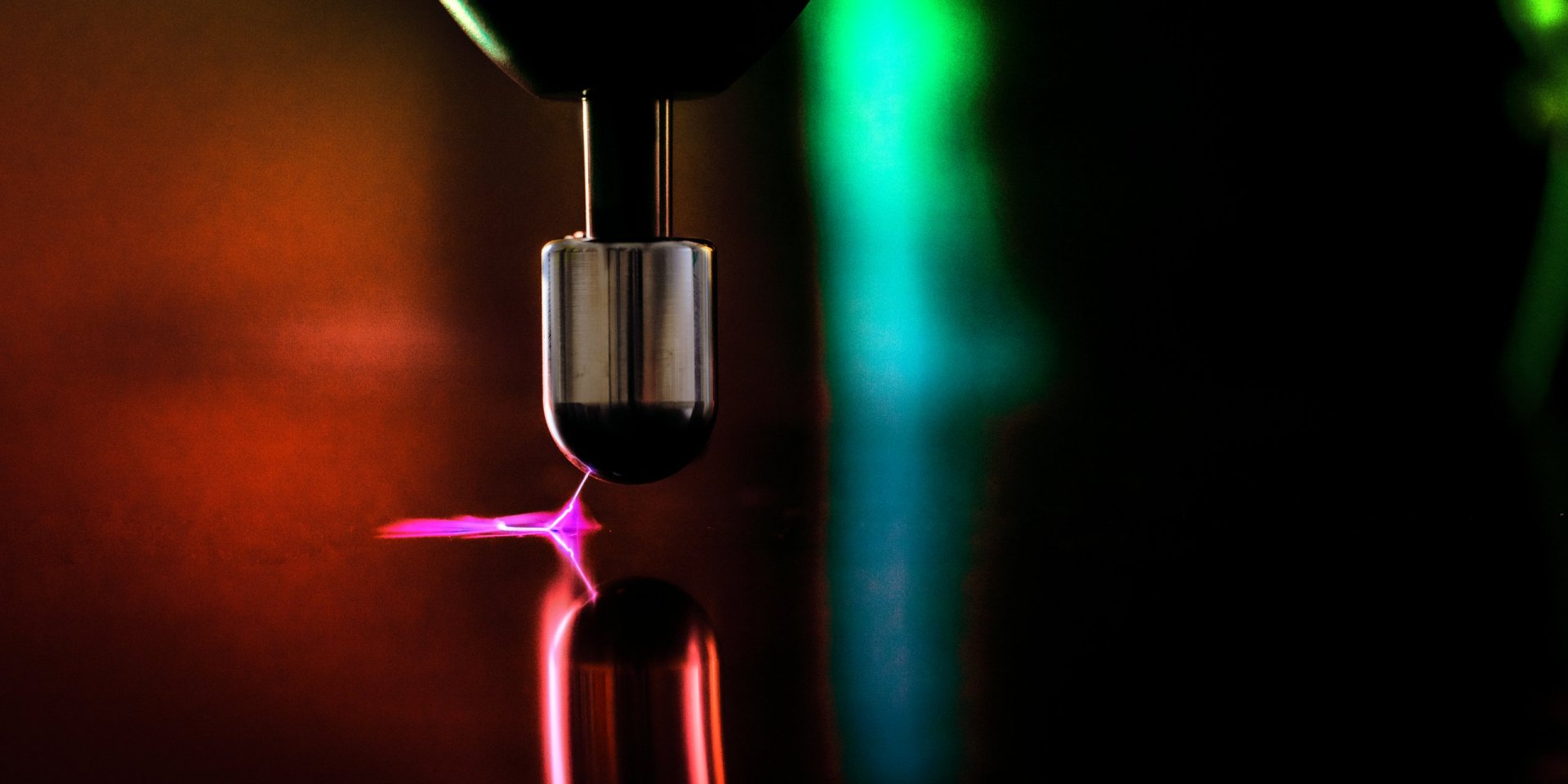

The Electromagnetic Compatibility Laboratory has modern equipment for electromagnetic compatibility testing.

Tests performed within the scope of the held accreditation of the Polish Centre for Accreditation No. AB 1684:

- Testing of immunity to electrostatic discharge (ESD) according to PN-EN 61000-4-2 (from 0.5 kV to 15 kV); RCN30 150-330

- Testing of immunity to a series of Electrical Fast Transients (EFT/B) according to PN-EN 61000-4-4 (from 200 V to 5.5 kV)

Tests performed within the scope of the held accreditation of the Polish Centre for Accreditation No. AB 1684:

- Testing of immunity to electrostatic discharge (ESD)

- according to PN-EN 61000-4-2, ISO 10605 (from 0.5 kV to 30 kV))

- [RCN30 150-330, RCN30 150-2000, RCN30 330-2000, RCN30 330-330] - Testing of immunity to shocks of type (1.2/508/20)µs according to PN-EN 61000-4-5

- IEC 61000-4-4, -5, -9 (1 and 3 phases)

- IEC 61000-4-4, -5, -9 (1 and 3 phases) - Testing of immunity to conducted disturbances induced by radio frequency fields according to PN-EN 61000-4-6

- IEC 61000-4-6 --- 150kHz - 80MHz (230MHz)

- ISO 11452-4 ---- (100kHz) 1MHz - 400MHz - Testing of resistance to voltage collapses, short interruptions and voltage changes according to PN-EN 61000-4-11

- IEC 61000-4-11, -29, -34 (1 and 3 phases)

- IEC 61000-4-11 - Measurements of disturbance emissions:

- Conducted according to PN-EN 55016-2-1(CISPR 16-2-1)

- Radiated according to PN-EN 55016-2-3 (CISPR 16-2-3) to 6GHz „Full Compilance”

- CISPR 16-1-1 (for measurements according to various EN 5500xx)

- CISPR 16-1-2 (for measurements according to various EN 5500xx)

- CISPR 16-1-4 (for measurements according to various EN 5500xx) - Measurement of conducted transients in on-board electrical installations of vehicles with 12 VDC and 24 VDC supply voltage and immunity testing of electrical and electronic equipment, components and devices installed on board motor vehicles and electric vehicles according to ISO 7637-2, ISO 7637-3 and ISO 16750 and defined as pulses 1, 2a, 2b, 3a, 3b, 4 ISO 7637-3 (I/O lines)ISO 7637-2 (50A) ISO 7637-2 (50A) ISO 7637-2, -3 (Pulses 1, 2a, 2b, 3a, 3b, 4)

- Test benches (set of apparatus) for:

- disturbance emission measurements, CISPR 16-1-1, CISPR 16-1-2, CISPR 16-1-4 (for measurements according to various EN 5500xx)

- testing of immunity of electrical and electronic equipment to conducted disturbances induced by radio frequency fields, IEC 61000-4-6 --- 150kHz - 80MHz (230MHz), ISO 11452-4 ---- (100kHz) 1MHz - 400MHz

- testing of immunity to voltage surges (IEC/EN 61000-4-5), series of electrical fast transients (IEC/EN 61000-4-4), collapses, short interruptions and voltage changes in single phase AC circuits (IEC/EN 61000-4-11) and DC circuits (IEC/EN 61000-4-29), 50 Hz / 60 Hz mains frequency magnetic field (IEC/EN 61000-4-8), pulsed magnetic field (IEC/EN 61000-4-9)

- testing of immunity of electrical and electronic equipment to electrostatic discharge ESD with an exposure level of up to 30 kV, IEC 61000-4-2, ISO 10605 (RCN30 150-330, RCN30 150-2000, RCN30 330-2000, RCN30 330-330),

- testing of immunity of electrical and electronic equipment/assemblies mounted on board motor vehicles against standardised disturbances according to ISO 7637-2, ISO 7637-3 and ISO 16750 and defined as pulses 1, 2a, 2b, 3a, 3b, 4)

Tests are also carried out in underground conditions and IN SITU (at the installation site and/or as indicated by the client).

Other activities carried out outside the scope of the held accreditation of the Polish Centre for Accreditation No. AB 1684, including measurements:

- Thermographic measurements

- Verification of effectiveness of overload/short-circuit protections

- Verification of correctness and efficiency of leakage protections

- Verification of correctness and efficiency of protections controlling continuity of earth conductors

- Testing of the parameters of electrical accumulators

- Checking the correctness of settings of electrical safety devices

- Periodic inspections of electrical equipment (e.g. welders, voltage indicators, switchgears, etc.)

- Post-accident opinion/assessment

- Technical opinion

- Technical acceptance

- Post-assembly acceptance

- Consultancy on the development of an EMC test plan

- EMC engineering research

- Isolation resistance testing

- Verification of electrical strength of insulation

- Testing of the effectiveness (tripping) of overload and short-circuit protection devices

- Testing of leakage protections

- Measurements of the continuity of earth conductors

- Resistance measurement of protective earthing

- Measurement of resistance of lightning protection earthing

- Measurement of resistance, conductive connections, electrical bonding

- Measurement of short circuit loop impedance

- Soil resistivity measurements

- Measurement of surface resistance, point to point, earth leakage, volumetric measurements

- Testing with regard to anti-electrostatic properties of materials, plastic products

- Testing of the effectiveness of residual current devices (RCD)

- Thermographic measurements

- Checking the correctness of settings of electrical safety devices

- Testing of the electrical installation of self-propelled mining machines

- Consultancy on the development of an EMC test plan

- Man-hour during EUT design changes to meet requirements

- EMC engineering research

- Electrical resistance measurements between metal parts of major components of the test object

- Measurement of the resistance of continuity of electrical bonding earthed to earth of the test object, not earthed

- Testing of correct functioning of insulation control systems

The aforementioned tests also apply to the electrical installations of machines and equipment not subject to approval by the Office of Technical Inspection.

Tests are carried out in accordance with the Regulation of the Minister of Energy of 23 November 2016 on detailed requirements for the operations carried out by underground mining works (Journal of Laws of 2017, item 1118), as well as relevant standards and regulations in force at the place of use.

We perform all tests and measurements using modern instruments that are calibrated and checked periodically (with a valid calibration certificate).

Elektrotechnika

Utrzymanie w ciągłej sprawności maszyn, urządzeń i instalacji elektrycznych jest dla nas zadaniem priorytetowym oraz definiującym działalność naszego Oddziału Elektromechaniki.

Radiokomunikacja

Na przestrzeni ostatnich latach pierwotnie zabudowaliśmy a obecnie utrzymujemy w stałej sprawności technicznej system łączności podziemnej we wszystkich Oddziałach Górniczych KGHM.

Automatyka

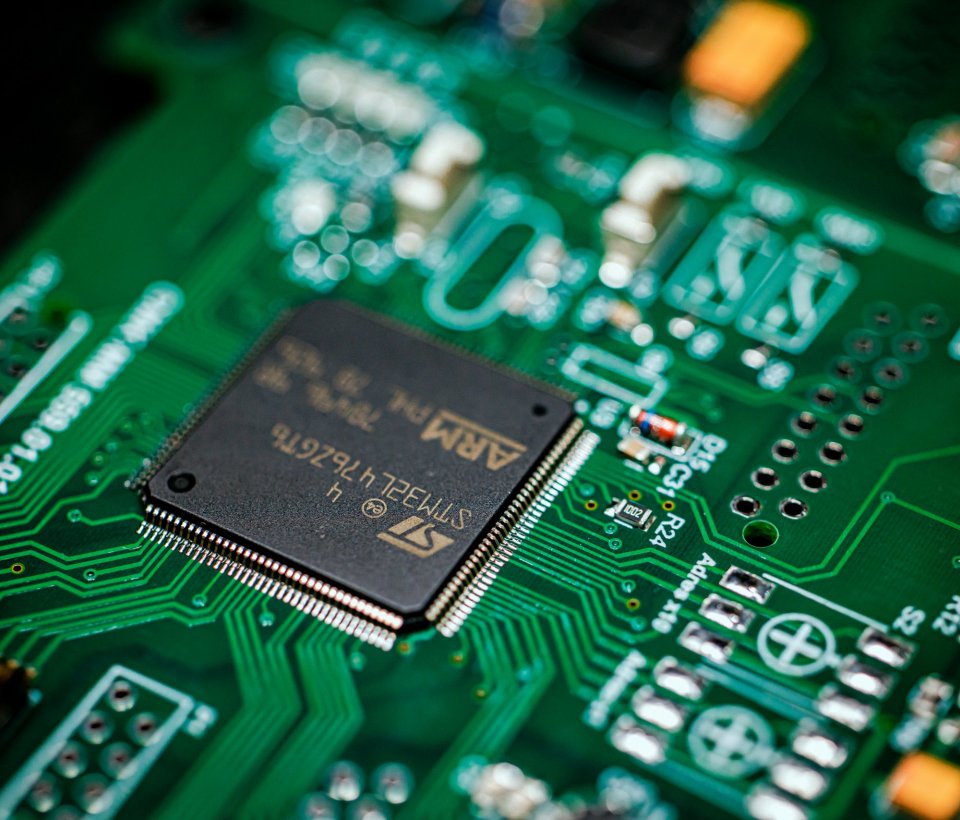

Projektujemy urządzenia automatyki oraz elektroniki przemysłowej. Posiadamy dużą zdolność do szybkiego opracowywania nowych rozwiązań oraz wdrażania ich do powszechnego stosowania.

Mechanika

Głównym produktem branży mechaniki są tamy wentylacyjne. Posiadamy w swoim portfolio ponad 20 modeli tam w różnych wariantach wykonania i towarzyszących im systemów automatyki.

Akredytowane Laboratoria

Laboratorium Kompatybilności Elektromagnetycznej i Badań Elektrycznych, Laboratorium Badawcze (Pracownia Odbudowy Górniczej oraz Pracownia Akustyki) oraz Biuro Certyfikacji Wyrobów.

Elektronika

Posiadamy wieloletnie doświadczenie w projektowaniu i produkcji elektroniki. Realizujemy zadania od pomysłu poprzez projekt do gotowego produktu przy zastosowaniu nowoczesnych technologii.

Obsługa lampowni

Lampownia stanowi newralgiczny punkt w ruchu zakładu górniczego oraz istotny element w zapewnieniu bezpiecznej pracy. Nasze usługi wymiernie wpływają na pracę Oddziałów Górniczych.

Serwis łączności radiowej

Na przestrzeni lat Spółka zabudowała, a obecnie utrzymuje w stałej sprawności technicznej system łączności podziemnej na wszystkich Oddziałach Górniczych KGHM Polska Miedź S.A.

Elektromechanika / utrzymanie ruchu

Utrzymanie w ciągłej sprawności maszyn, urządzeń i instalacji elektrycznych jest zadaniem priorytetowym oraz definiującym działalność naszego Oddziału.